easyfloc - the recipe for success in prefabrication with loose insulation materials.!

The technology.Higher performance, greater precision, more economy.

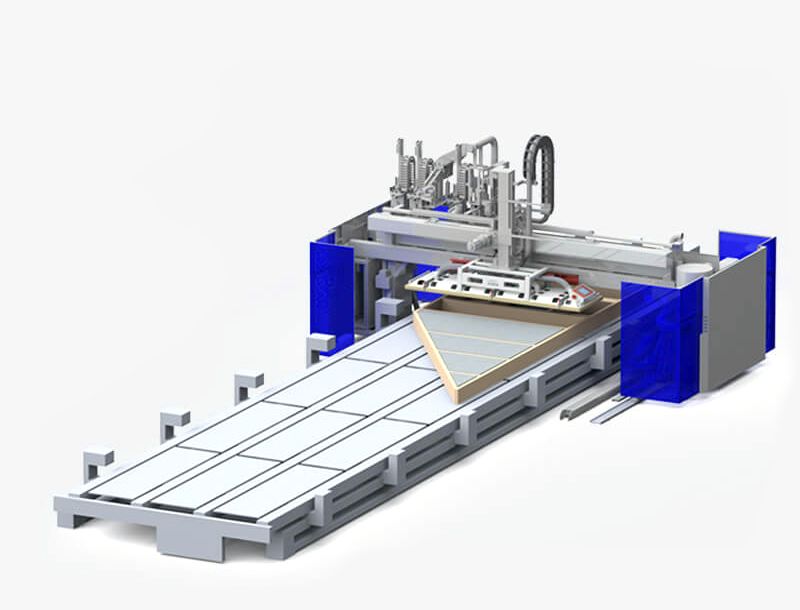

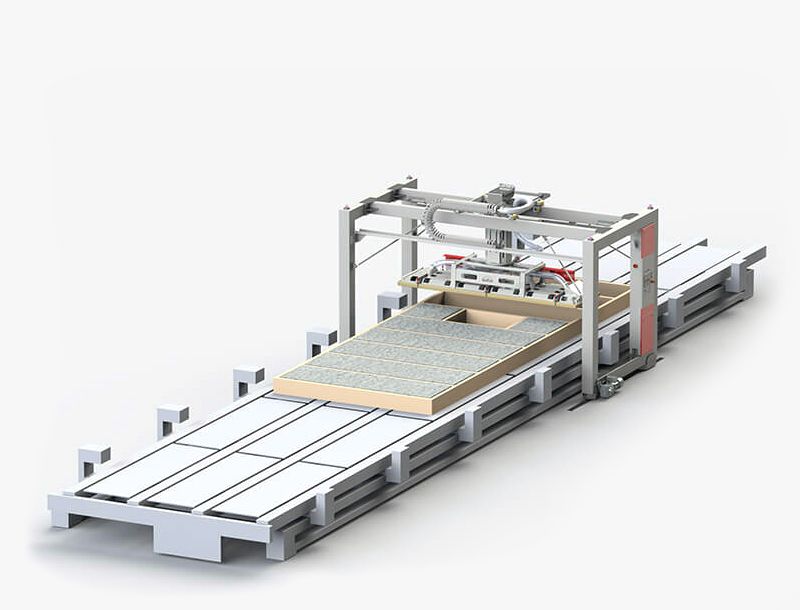

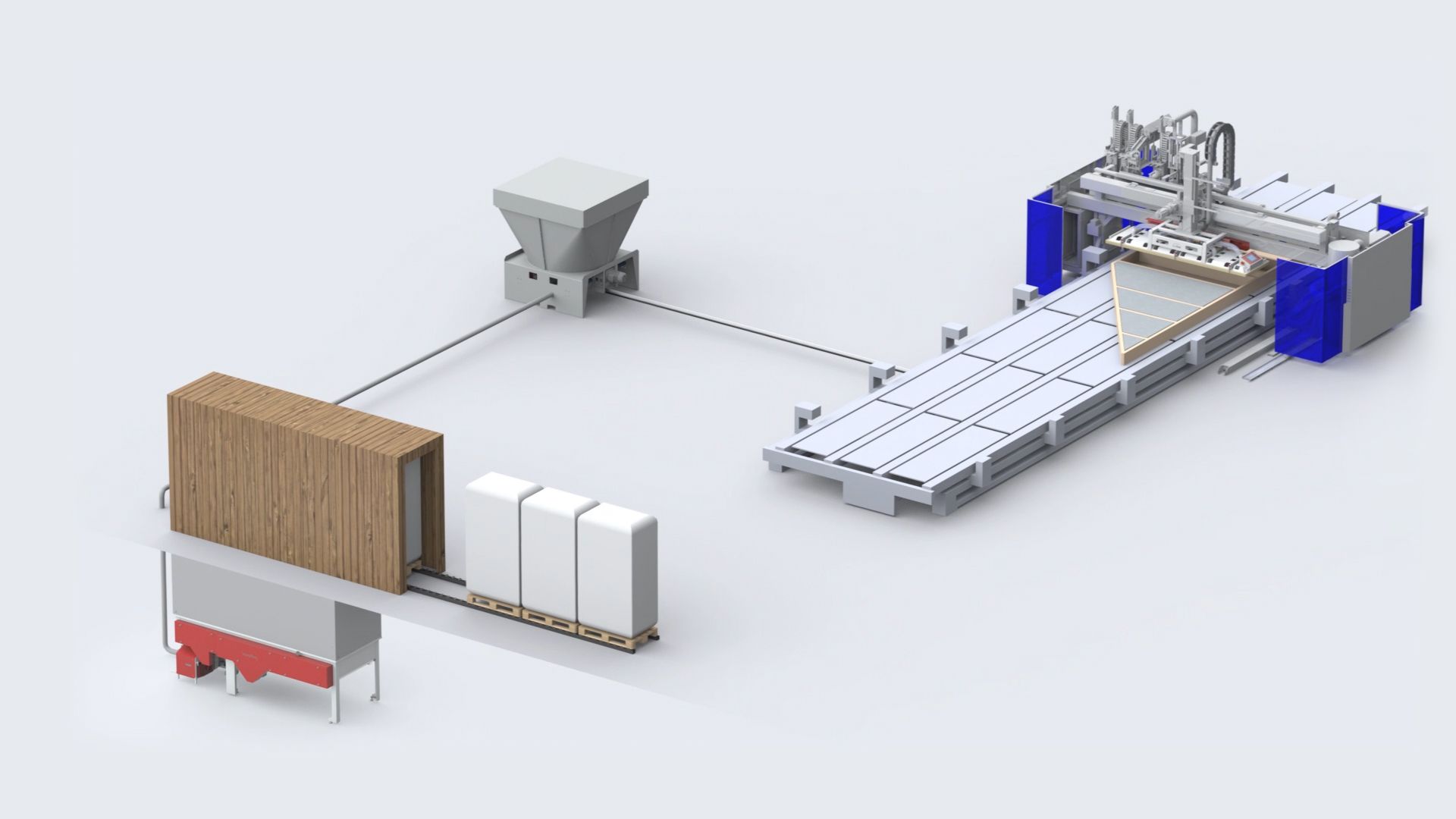

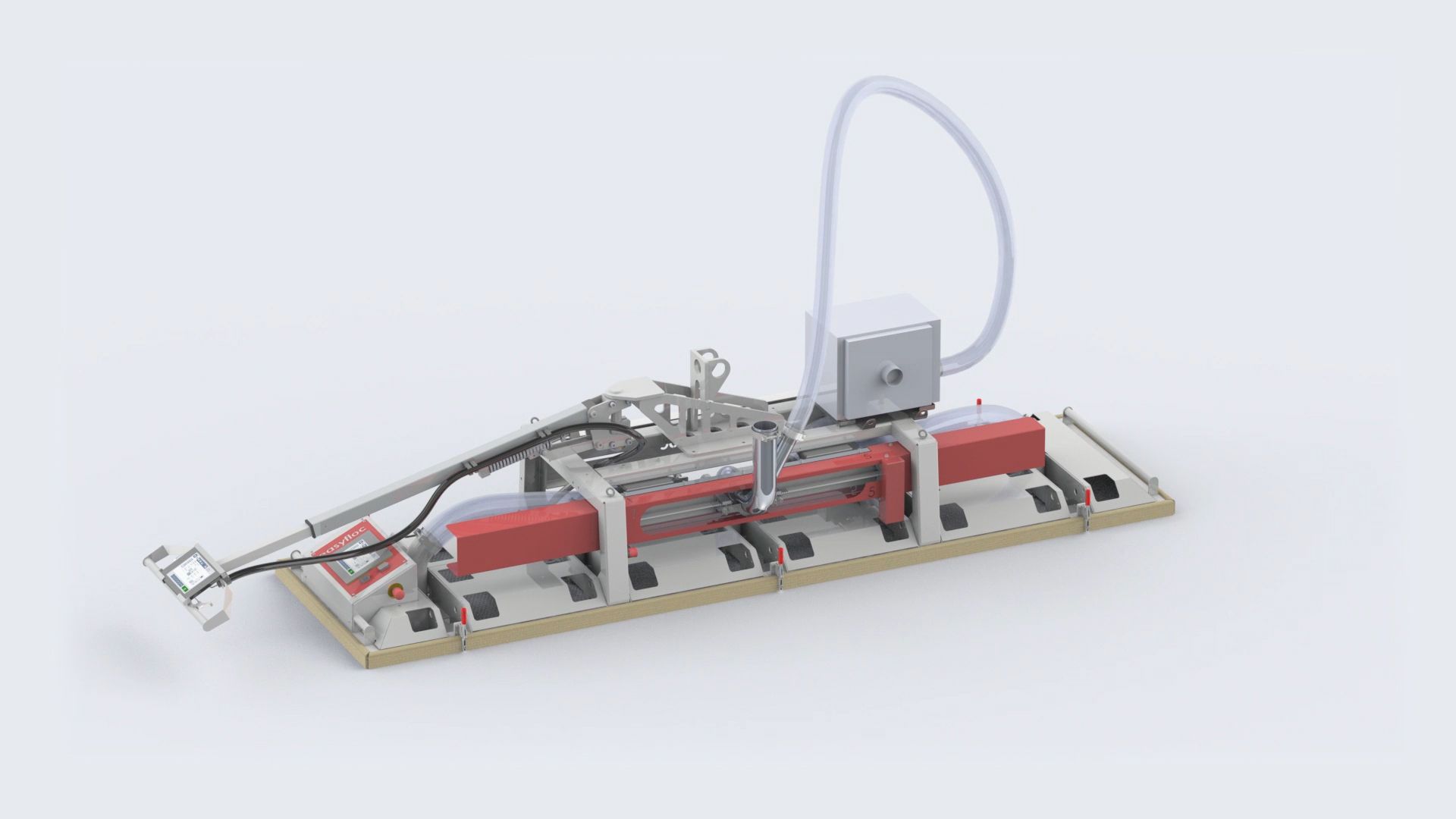

easyfloc is designed for integration into existing or new production lines and ensures uninterrupted processes. The industrial insulation system is modular and grows with the user's requirements.

The insulation panel.The original with air-permeable membrane.

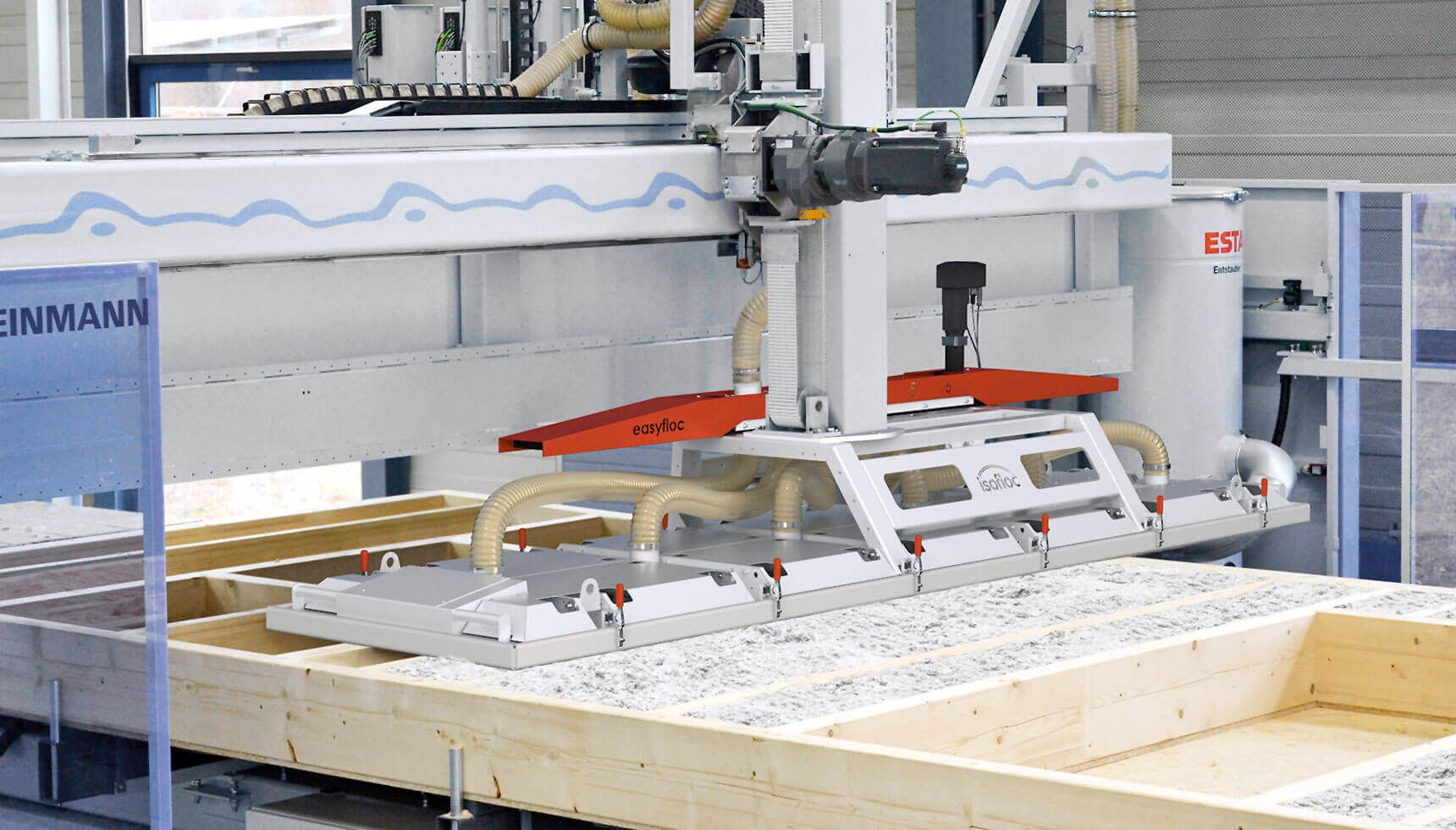

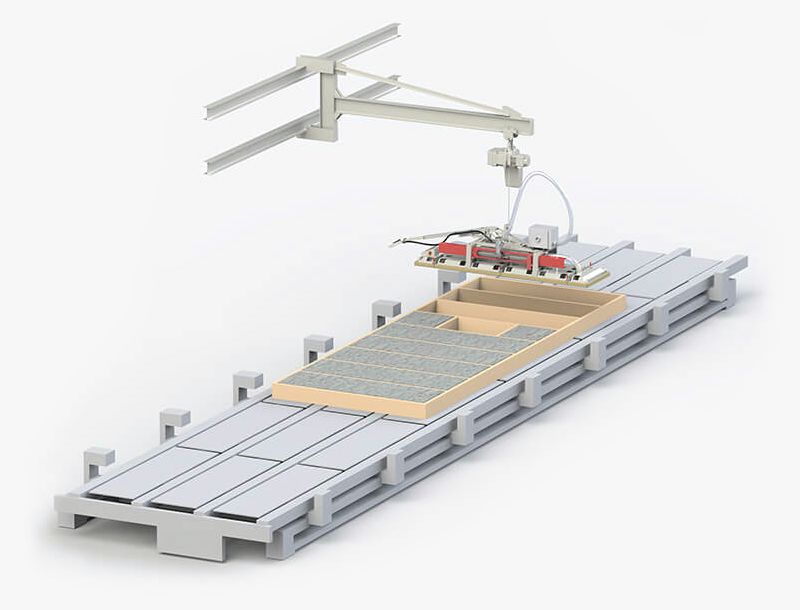

The easyfloc insulation panel for prefabricated wood construction elements is indispensable in industrial wood construction. The user-friendly operation via touchscreen or fully automatic with CAD data, the low-dust insulation process, the integrated quality assurance, and the industry's fastest insulation process ensure outstanding cost-effectiveness.

Download PDF

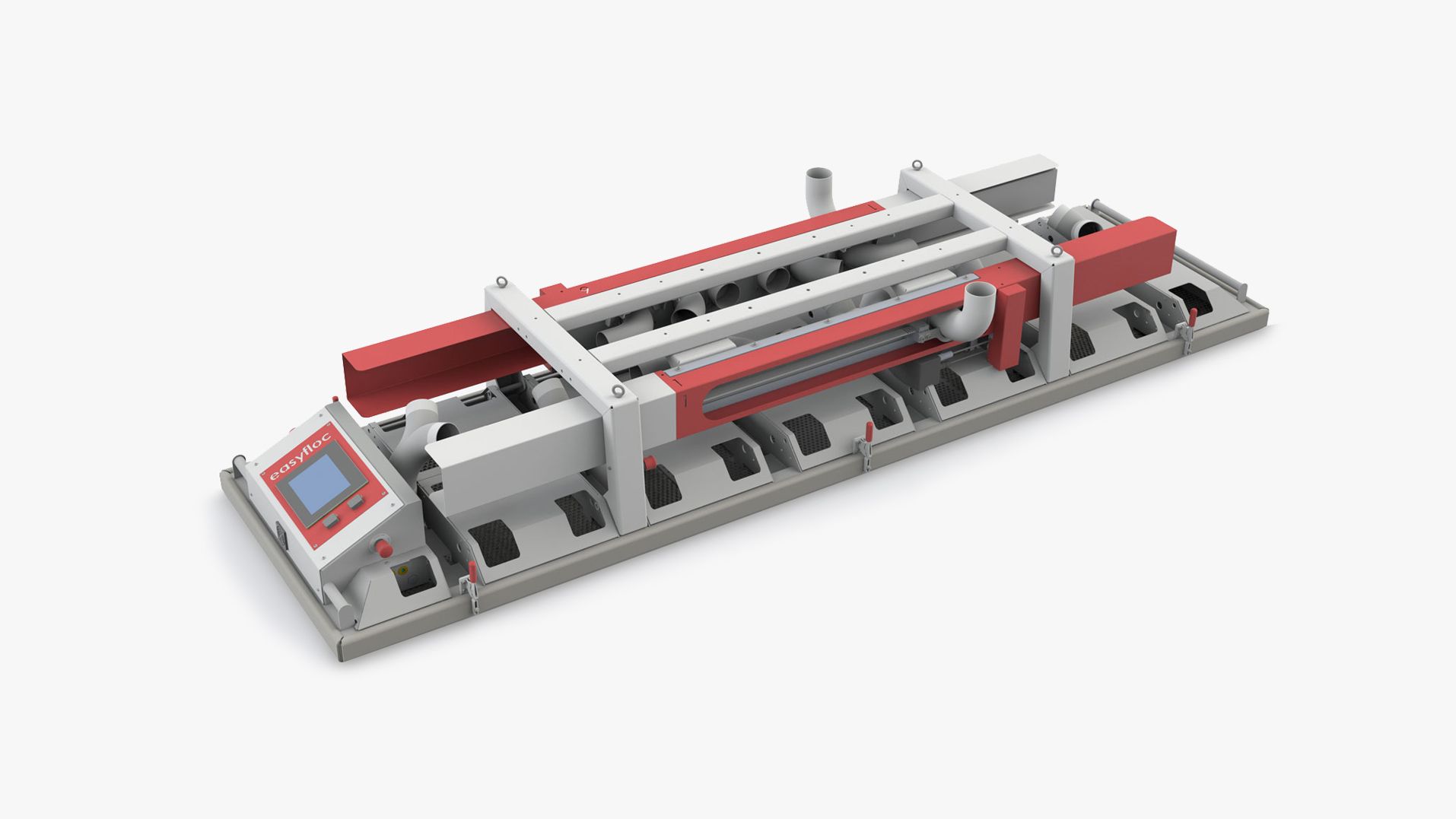

Even faster insulation process of the new G4 easyfloc blow-in panel: The G4 easyfloc blow-in panel from isofloc has two feed lines and six blow-in nozzles for fast, precise and low-dust filling in the prefabrication of timber frame construction elements.

Not without reason the No. 1: With easyfloc you reduce personnel expenses, production and changeover times to the absolute minimum and you still benefit from maximum quality and efficiency.

The connection variants. Automation levels for your needs.

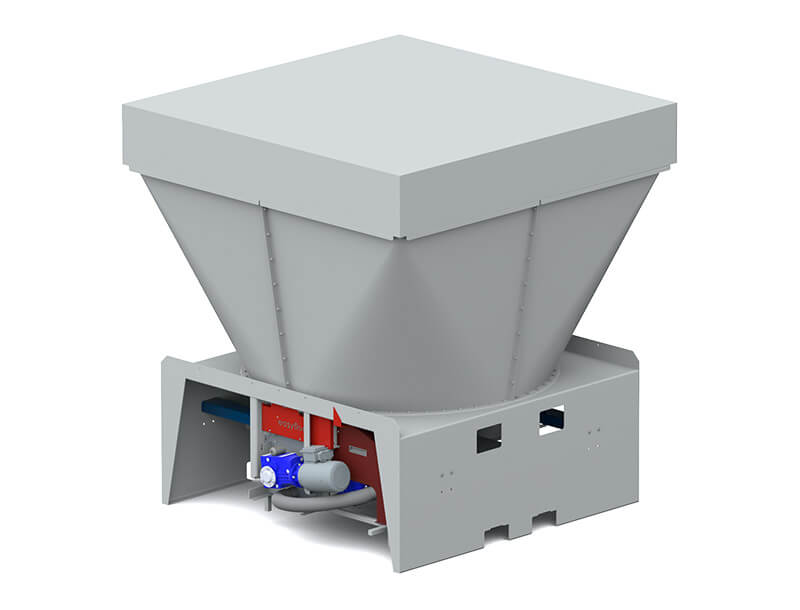

Stockpiling. From the insulation machine to the bunker.

The insulation materials. Full flexibility for every project.

The practical success. Leading timber builders rely on easyfloc.

The services. For all-round successful operation.

Live-Demo. Experience easyfloc in the factory.

We will be happy to answer all your questions and personally take care of your needs: We look forward to getting to know you!